Eastman is excited to announce a partnership with Patagonia to address textile waste.

- Email Info@texfuture.com

Press Release

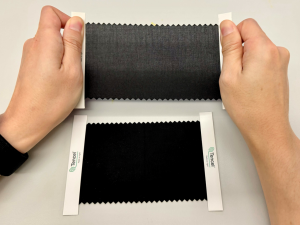

Lenzing Unveils The New Potential Of TENCEL™ Lyocell Fibers As Alternative Material For Stretch Fabrics

Lenzing Group, a global producer of wood-based specialty fibers, announces a new processing technique of TENCEL™ branded lyocell fibers tailored to create stretch fabrics that enhances comfort of the wearer. This solution offers a fossil-free alternative that delivers exceptional stretch and recovery properties while adhering to responsible production methods.

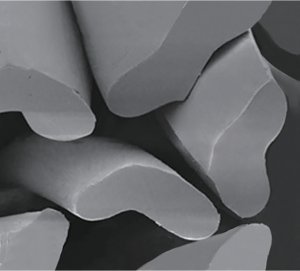

Teijin Frontier Announces Development Of Microft™ MX, A New Material For Sports And Outdoor Wear

Teijin Frontier Co. Ltd., the Teijin Group’s fibers and products converting company, today announced the development of Microft™ MX, a next-generation, high-quality, high-performance material. This product is made from highly-deformed cross-section multifilament yarn*, which is a uniform mixture of single filaments of polyester and nylon, using a unique spinning technology, as the optimal woven or knitted structure. The evenly mixed polyester and nylon filaments produce deep colors.

lululemon And Samsara Eco Unveil World’s First Enzymatically Recycled Nylon 6,6 Product

lululemon, in partnership with Australian enviro-tech startup, Samsara Eco, has unveiled the world’s first enzymatically recycled nylon 6,6 product, marking a key milestone in textile-to-textile recycling and lululemon’s work to create a circular ecosystem.

Premium high street retailer Cos has partnered with Merino wool specialist Nativa on a limited-edition capsule collection championing regenerative farming practices “that aim to nurture positive change”.

Under Armour is partnering with precision testing solutions supplier James Heal to address the invisible sustainability threat microfibres and microplastics pose to the environment.

The sportswear brand is working with UK-based James Heal to make its microfibre-shred test available to the wider industry to help understand and mitigate the impact of synthetic and natural fabrics shedding fibres during production, wear, and cleaning.

Kyle Blakely, senior vice president of innovation for Under Armour, said in a statement: “Until now, integrating fibre-shed testing into industry research and development activities has required a significant time and cost investment.

“At Under Armour, we believe intervening early to mitigate shedding is critical, which is why our test method is designed to specifically address these time and cost barriers to entry. Thanks to our partners at James Heal, we are excited to make our innovative test method widely available as we address our own environmental impact.”

In addition to making the test method publicly available, Under Armour has provided complimentary test kits to high-volume textile mills in its global supply chain to encourage early intervention within its indirect scope.

Under Armour has also launched a new pilot programme to develop a reduced shed version of its largest fleece offering that is expected to launch in autumn/winter 2024. This is part of the sportswear brand’s commitment to ensure 75 percent of its products are made of low-shed materials by 2030.

Sam Tissington, commercial director at James Heal, added: “Fibre-shedding in the textile industry is an extremely prevalent topic, and we are as keen as any to support ways to reduce this.

“We are proud to support Under Armour in their attempts to further reduce the shedding of fibre throughout the manufacturing process of textiles, and to show that support we are providing global access to the Under Armour test method with the purchase of the Under Armour compiled Fibre-Shedding kits.”

Source: Fashionunited

LENZING, Austria — January 24, 2024 — Lenzing Group, a leading global producer of wood-based specialty fibers, announced an exciting collaboration with China’s internationally recognized denim mill, Advance Denim, to use matte TENCEL™ Lyocell fibers for their latest Denim Collection. As a long term partner for more than 15 years, this collaboration marks a significant milestone in the pursuit of bringing planet-conscious denim solutions that combine style and comfort to consumers.

Carrington Textiles: Exhibiting Stretch Flame Resistant Textile Innovations In The Middle East

Global manufacturer of flame resistant fabrics, Carrington Textiles, is exhibiting its latest developments in stretch FR and sustainable workwear products, at Intersec in Dubai in January 2024.

Polygiene launched the Polygiene ShedGuard innovation project at the ISPO trade show, aiming to minimise microfibre loss and improve fabric wear resistance during washing.